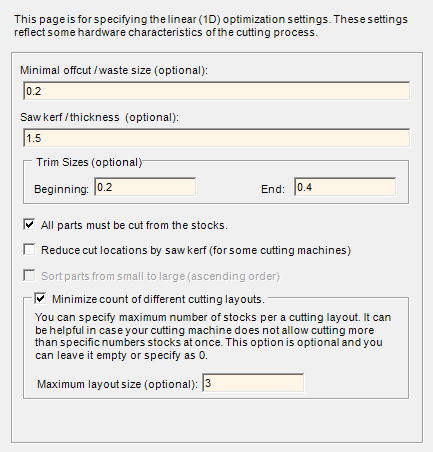

The dialog specifies project calculation settings.

Depending of the requirements of your project you can tune-up the optimization calculation by some additional settings. 1DCutX provides the following settings:

This parameter specifies the minimal size of the waste part (offcut) that can be cut from the stocks. It plays an important role for the glass or stab cutting when it’s hard or impossible to cut a tiny piece from the stock, because of the tools limitations.

If you specified minimal offcut value then 1DCutX would produce cutting layouts with no waste or with waste sizes more or equal to this value.

When stock gets cut by a saw and high degree of accuracy is desired then this parameter is important. It defines the size of the gap between the parts that is a result of material removal by the saw.

Some stocks come with rough ends that have to be trim out before the usage. These parameters specify how much stock will be trim out from the beginning and end of the stocks.

For some projects you could have more parts to cut than stocks available.

Example.

You have to cut 100 parts of length 50 and 40, but you have only 5 stocks of length 160. Hence it’s impossible to cut all parts.

In that case you can check off this box and 1DCutX will use all stock and as much as possible parts, but not all of the parts.

However, if you need to cut all parts then you should check this box on.

This option subtracts the saw kerf (saw width) from the location of the cuts. It's helpful for cutting machines that take a saw kerf into account automatically.

When checked this option puts large parts at the end of stocks. If the option is unchecked (default) then it puts large parts at the beginning of stocks.

If you want to reduce the number of cutting operations then this option is for you. It’s referred sometimes as a batch cutting and allows cutting several stocks simultaneously; effectively reduce the cutting operation by the number of stock in a batch.

Note.

If you used this option the results will be less optimized, since 1DCutX will try to reduce the cutting layout instead of the material waste.

The following images demonstrate the option in an action:

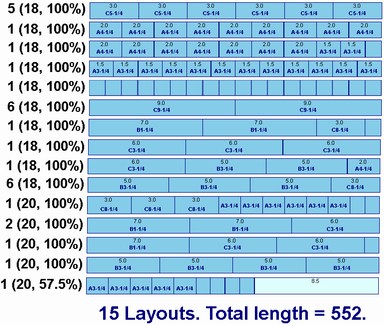

1. When we ran a project without the layout minimization function we got 15 different layouts with total used stock of 552":

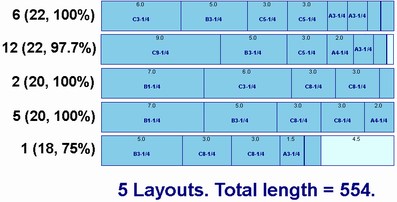

2. Another run with the layout minimization produced only 5 different cutting layouts, albeit used 554" of the stock:

You can specify maximum number of stocks per a cutting layout. It can be helpful in case your cutting machine does not allow cutting more than specific numbers stocks at once. During calculation 1DCutX will generate layouts that will have the specified number or less stocks in one layout.